WPC science knowledge

Wood-plastic composites (WPCs) are composite materials made from wood fiber/wood flour and thermoplastics such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) or polylactic acid (PLA).

In addition to wood fibers and plastics, WPC can also contain other lignocellulose and/or inorganic filler materials. WPC is a subset of a large class of materials called natural fiber plastic composites (NFPC), which may not contain cellulose-based fibrous fillers such as pulp fibers, peanut husks, coffee husks, bamboo, straw, biogas residues, etc.

The chemical additives in the composite structure appear to be almost "invisible" (except for mineral fillers and pigments, if added). They provide the integration of polymer and wood flour (powder) while promoting optimal processing conditions.

WPC does not corrode and is highly resistant to rot, rot and marine borer attack, although they do absorb water into the wood fibers embedded in the material. Water absorption is more pronounced in WFCs with hydrophilic matrices such as PLA, and also results in reduced mechanical stiffness and strength. Acetylation treatment can improve mechanical properties in humid environments. WPC has good machinability and can be shaped using traditional woodworking tools. WPCs are generally considered a sustainable material because they can be made using recycled plastic and waste from the wood industry. While these materials extend the useful life of used and discarded materials, they also have a considerable half-life; added polymer Compounds and binders make WPC difficult to recycle after use.

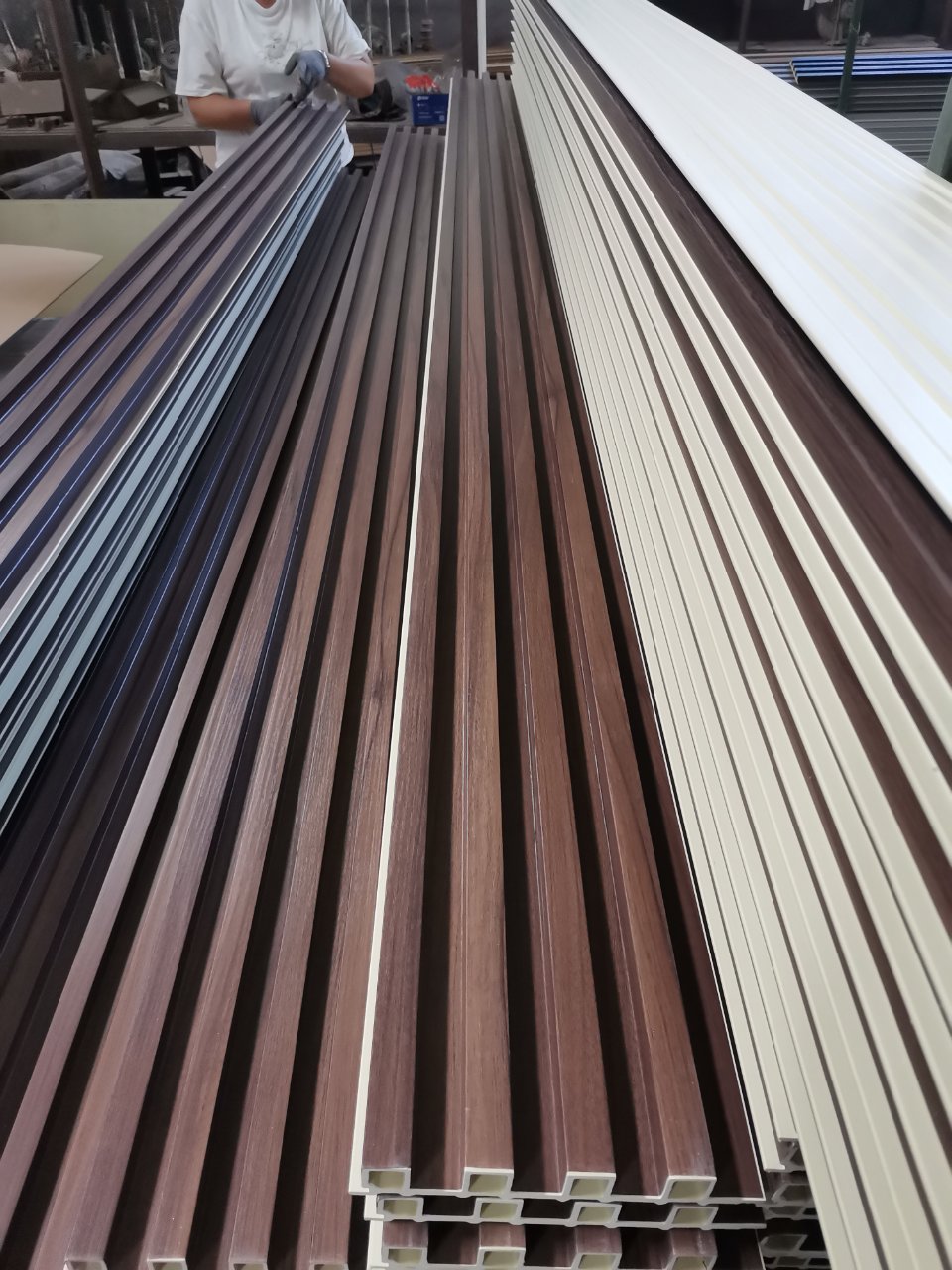

However, they can be easily recycled in new WPC, just like concrete. One advantage over wood is that the material can be moulded to meet almost any desired shape. WPC members can be bent and fixed to form strong arched curves. Another major selling point of these materials is that they do not require paint. They are manufactured in a variety of colors but are widely available in gray and earth tones. Despite having a cellulose content of up to 70% (although 50/50 is more common), the mechanical properties of WPC are most similar to pure polymers. Pure polymers are polymerized without the addition of solvents.

This means that WPCs are lower in strength and stiffness than wood, and their behavior is time and temperature dependent.

Wood particles are susceptible to fungal attack, but not as much as solid wood, and the polymer components are susceptible to UV degradation.

Freeze-thaw cycles may reduce strength and stiffness, although testing is still ongoing in the field. Some WPC formulations are sensitive to staining by various reagents.